Subsurface engraved crystal glass is being used more frequently for awards, trophies, and displays of recognition. These beautiful mementos provide an elegant and lasting way to not only preserve a moment or picture, but to do it in a way that’s both tasteful and eye-catching.

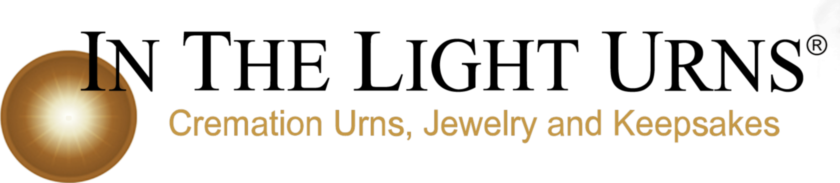

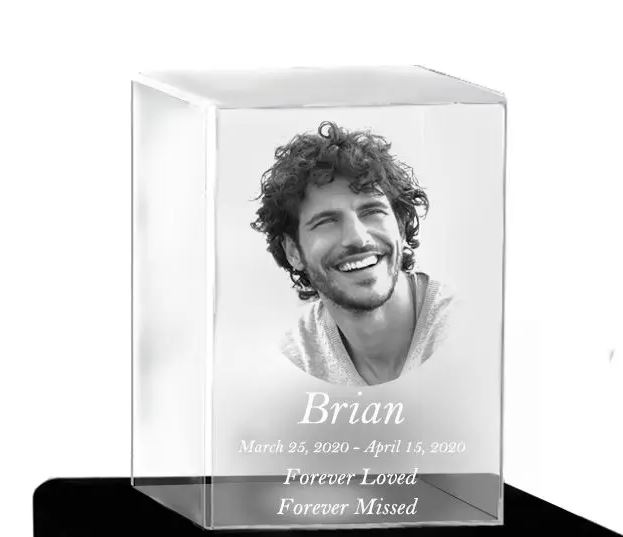

Honoring and memorializing a loved one in crystal glass is an increasingly popular application of 3D subsurface engraving. A beautiful memorial crystal with a 3D picture engraved inside is a truly special way to celebrate those we love.

When you decide to commission a crystal glass 3D subsurface engraving you want to know you’ll get excellent quality and that it will last. What some engravers won’t tell you is that quality and durability do vary. Some claim their glass is “standard” and others say they use “high-grade crystal glass”, but what does that all mean? You might be paying more than you should for an inferior quality material.

We want to make sure our customers know exactly what quality of crystal glass memorial they are buying. In the sections below we’re going to explain the different types of crystal and how they influence quality and durability. To do that though, we’ll need to explain the subsurface engraving process and how a picture is converted to a 3D image inside the crystal.

Our hope is that when you finish this article you’ll know what type of crystal you want in the memorial we’re going to create for you. If you’re still unsure when you reach the end, talk with us about your needs and expectations and we’ll give you whatever additional information you need.

For simplicity and clarity, this article is divided into the following sections:

- What is a 3D Subsurface Image?

- Creating Micro-cracks

- Properties of Window and Optical Glass

- Properties of Crystal Glass

- Crystal Glass and the Laser Engraving Process

What is a 3D Subsurface Image?

When people look at an image that’s been created inside a solid crystal the first question they usually ask is, “How did they do that?”

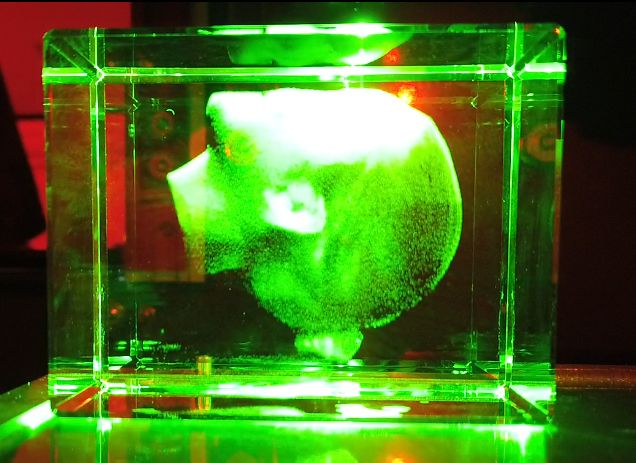

An image is composed of thousands, possibly millions, of microscopic cracks. Just like a crack in a windshield or glass, when viewed from a particular direction a micro-crack stops light passing through the material. Instead, you see a reflection that usually looks white or silver.

In a 3D subsurface image each crack stops light passing through and creates reflections. Careful placement of these cracks in the crystal builds up a picture in much the same way that print and pictures on a newspaper page are actually composed of many little dots. The difference with the 3D image is that these dots are spaced out in height or depth as well as up and down, left and right. (An engineer would say that while the newspaper letters and pictures have x and y dimensions the 3D image also has a vertical or z dimension.)

Creating Micro-cracks

Now you know the image is composed of thousands of tiny cracks, each one precisely placed in x, y and z directions, the next question is, how did they get there?

The simple answer is that it’s done with a laser. The full answer is a bit more involved.

You probably know that if you use a magnifying glass to focus the light from the sun to a very small spot, you can create enough heat to burn paper. Well subsurface micro-cracks are made much the same way.

Rather than use the sun, subsurface engraving machines use a laser. Laser light is different to regular light in two important ways. It’s a single color or wavelength, and all the photons that compose the light are moving together rather than jumping around. These attributes give it a lot of energy.

Focusing the light from a laser through a lens to a tiny spot concentrates that energy in a very small area. If that spot is inside crystal glass it creates a small hot region that wants to expand. The bulk of the crystal around it is still cool though, so stress builds up at the spot where the laser is focused and that creates a tiny crack.

To put some numbers on all this, high quality laser engraving machines use a green laser where the wavelength of the light is about 532 nanometers. This is focused down to a spot about 40 – 80 microns (0.0016 – 0.0032”) in diameter, which is about the size of the micro-crack created by a single burst of energy.

The wavelength of the light is important in achieving this small spot size. It’s harder to focus red light to a spot this small, and if you ever see a blue laser machine, know that it can probably focus to an even smaller spot size.

The other point that’s very important is the quality of the crystal. Understanding why that is starts with an explanation of what makes crystal glass special.

Properties of Window and Optical Glass

Glass is known for being transparent. The interesting thing though is that most of the glass around us isn’t that transparent. Try looking through the bottoms of a set of drinking glass that have been stacked and you’ll notice it’s rather like looking through fog. This is because the glass that’s used in windows and drinking glasses isn’t optically perfect. In fact, it only transmits about 90% of the light that falls on it. Some is scattered as it passes through the glass, a little is absorbed and the rest is reflected from the surface.

A second problem with glass is that it bends light passing through it. Strictly speaking, this bend happens at the glass-air interface. It’s called refraction and it’s why a pencil placed partly in water appears to have a bend. Refraction is also the reason why, when you look at a piece of glass from a shallow angle it acts like a mirror: rather than going into the glass, the light rays are reflecting back off the surface.

Where things get really complicated is that refraction varies with wavelength of light. That means a window bends red light less than it bends blue light. (This, incidentally, is how light shining through glass creates a rainbow effect.)

Refraction and poor transmission due to scattering, create challenges for engineers designing camera lenses and binoculars. These need to transmit as much light as possible, without bending or distortion. To achieve this, there’s optical glass.

Optical glass is produced by changing the recipe from what’s used for window glass. Window glass is composed mostly of silica (technically, silicon dioxide, which is a form of sand,) plus soda (sodium oxide) and lime (calcium oxide.)

Optical glass still has a silica base but uses either lead, boric oxide or barium for improved optical performance. These additives give it a higher index of refraction, higher transmissivity and less scatter or dispersion. Or, to put that another way, it’s clearer and there’s less distortion.

The manufacturing process also influences glass quality. Optical glass is made in smaller quantities than regular window glass, and greater care is taken over how it’s mixed, melted and poured. In contrast, window glass contains tiny bubbles and impurities that deflect and scatter light passing through.

Different recipes create different types of optical glass. The three types you see written about most often are borosilicate BK7, K9 and BaK4. (K9 is essentially the same as BK7)

Within those types there are multiple grades with subtly different formulations. Lead-free glass is indicated by an “N” prefix, like N-BK7. Glass made with at least 24% lead is referred to as “lead crystal” but not all crystal glass contains lead. This means it’s time to discuss what does and doesn’t qualify as crystal glass.

Properties of Crystal Glass

Two properties distinguish crystal glass from that used in windows. These are the index of refraction – also called the refractive index – and the Abbe number.

We haven’t mentioned the Abbe number until now but it’s another measure of refraction. More specifically, it’s a measure of how much refraction varies with color. To be confusing, glass that has less color scattering – chromatic aberration – has a higher Abbe number. Good optical glass has an Abbe number greater than 55. The number for BaK4 is 56 while BK7 is 64, just lower than diamond which is 65.

The other property is the refractive index. This is a measure of the angle through which light bends at the glass-air interface. The bend gets bigger as the light strikes the glass at a shallower angle. Eventually the angle becomes so shallow that the light reflects back off the glass rather than passing through, which is the principle behind what makes the micro-cracks show up in the crystal.

The important point to remember about the refractive index is that a larger number means light changes direction more. That in turn gives the glass more of a sparkly appearance because it bounces light around inside more.

Optical glass, sometimes called crown glass — the “K” is from the German word “Krone” for crown — has a lower refractive index than glass intended for non-optical uses. The index of N-BK7 is 1.5 and for BaK4 it’s a little over 1.55. For reference, lead crystal, the kind wine glasses are made from, is 1.655, Swarovski crystal is 1.7 and diamond is 2.417.

Having followed this discussion, you may be wondering if there is a definition of crystal glass. The answer is that there’s nothing firm or rigidly defined. However, most crystal glass authorities use this definition: crystal glass has an Abbe number greater than 55 and an index of refraction greater than 1.5.

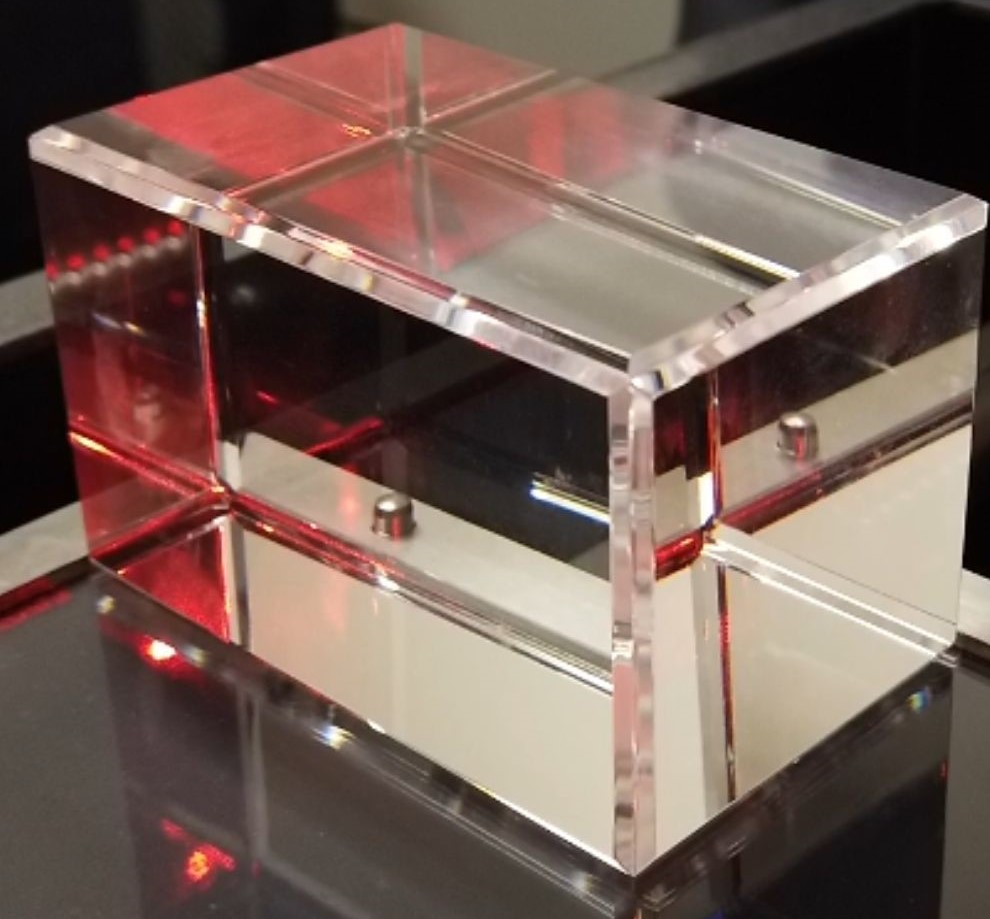

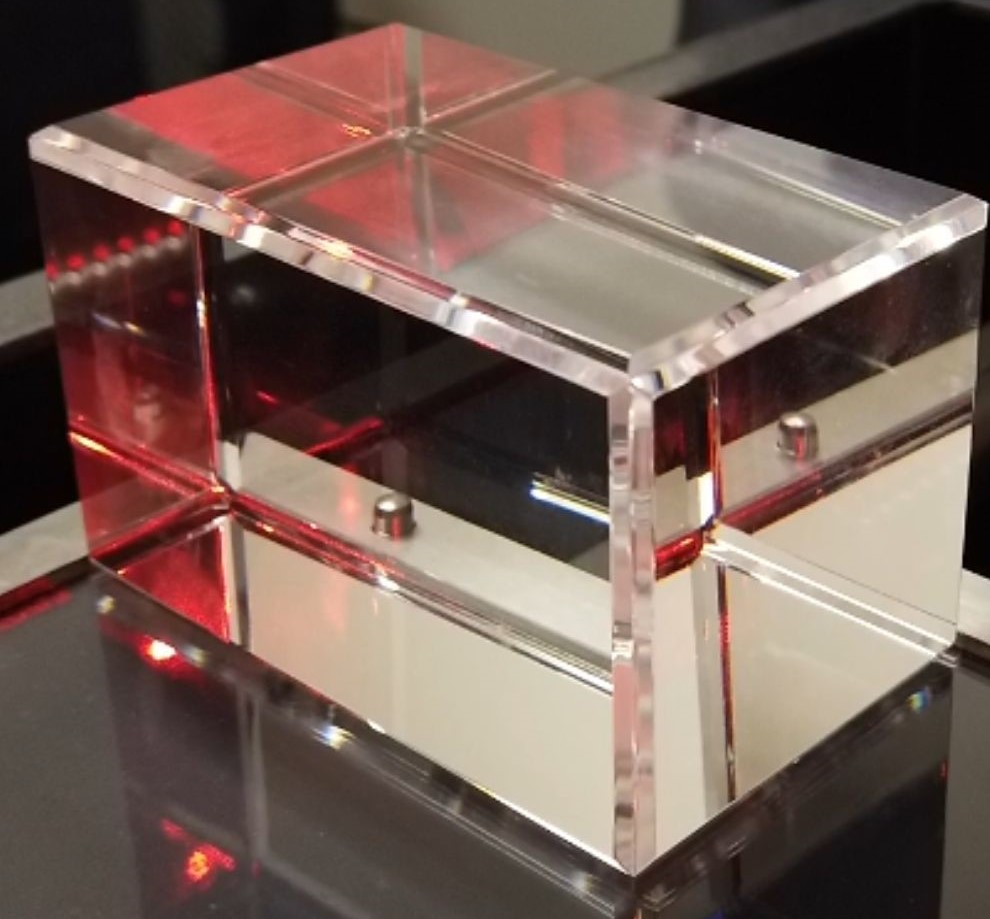

At In The Light Urns, we work with high quality optical glass or also known as K9. We have various forms, shapes and sizes of these crystal giving you a wide variety of options to memorialize your loved one. The Crystal Memory 3D Heart & Light Box and the Crystal Memory 3D Rectangle & Light Box are one of our top selling products. You can purchase these as memorials or as a complete beautiful urn set.

Crystal Glass and the Laser Engraving Process

Now that we've explained the different types of glass and their optical properties, let’s return to how an image is engraved inside a piece of crystal glass.

This starts with a photo of the person who’s going to be memorialized. It might also be a beloved pet, a treasured possession or some other object that you want capturing in three dimensions. Here though we’ll focus on how the process works with a face from a photo.

The photo is scanned into a computer where software creates a mesh or grid of points that define all the features. More software then wraps this onto the shape of a head. The computer then defines in x, y and z coordinates every location where a micro-crack is needed.

Now the crystal glass piece is loaded into the laser machine. The machine has a laser, (usually green,) with a lens in front. This lens focuses the laser beam down to a tiny spot. The spot is created at a distance from the lens that’s defined by the lens size and shape.

The laser machine is then provided with the coordinates of every intended micro-crack location. Moving from location to location, the machine positions the laser spot at the exact place inside the crystal needed to create the crack. The laser fires a short burst of light and the crystal cracks. Then the laser moves to the next spot and the process repeats. (A high-quality machine will position the laser with greater accuracy than a less expensive machine can achieve.)

When it’s creating the micro-cracks the laser tends to jump around over the glass. This is to avoid creating adjacent cracks with successive bursts. This could put too much heat into a small volume and risks making a larger crack that joins together.

If the crystal glass isn’t of optical grade and the beam spreads out inside, the micro-cracks won’t be positioned as accurately and may not be the size needed. The same applies if the refractive index isn’t exactly what the laser expects: the crack will be misplaced and the 3D engraving won’t be as clear and as detailed as you were hoping for.

It’s also very important that the crystal has the strength and integrity to resist cracking or even shattering as the laser does its work. This is something that’s a risk with poor quality crystal glass.

Discussing Your Needs and Expectations With Us

We are fully committed to providing the best quality and value possible for those looking into buying Cremation Urns, Cremation Jewelry, and now 3D engraved Memorial Crystals. It’s of the utmost importance to us that the finished crystal meets your expectations for image quality and clarity. This is why we want to make sure our customers know exactly what quality of memorial crystal they are buying.

Crystal glass 3D subsurface engraving is a relatively new way of creating awards, trophies and memorials. We’re happy to answer any questions you may have about it and won’t push you into making a decision. Our memorial specialists are available 7 days a week, so please call or use our Contact Us form to get in touch. Remember, your satisfaction is our highest priority.

Looking for more information on buying 3D laser engraved glass? Check out our article on 5 things to consider when buying a laser engraved glass item.